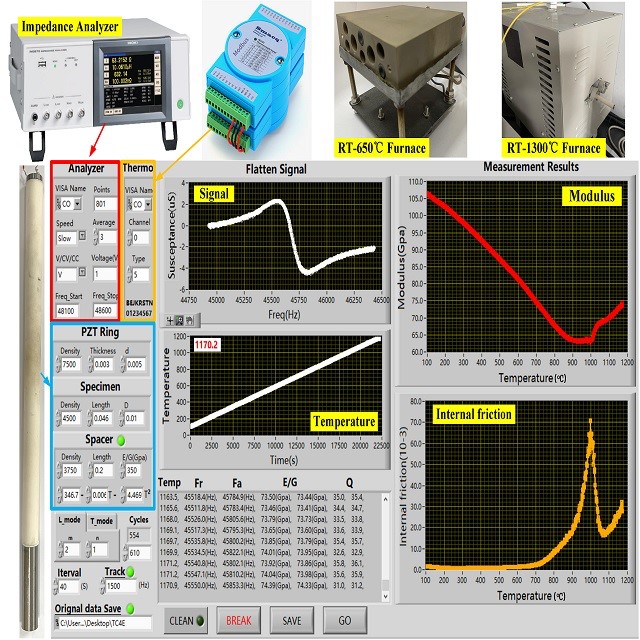

Peking University, December 16, 2021: Recently, the Li Faxin Research Group of Peking University College of

Engineering developed the world's first dynamic mechanical analyzer

(DMA) suitable for hard materials (metals, ceramics, etc.), as shown in

Figure 1 below. The instrument is based on the electro-mechanical

impedance method which can quickly, accurately, and automatically

measure Young's modulus, shear modulus, and corresponding internal

friction of materials under variable temperature conditions. The advent

of the instrument has brought good news to the high and low-temperature

mechanical analysis in the fields of superalloys (ceramics), composites,

functional materials, and amorphous alloys. It also means that China

has achieved an internationally leading position in this field. The

first author to complete the work is Xie Mingyu, a 2018 doctoral student

of the same research group.

Hard material DMA based on electro-mechanical impedance method and its automatic measurement software interface

Modulus and internal friction (or damping) are the basic physical

properties of all solid materials. Their changes with temperature can

accurately reflect the internal evolution of materials, such as atomic

diffusion, grain boundary sliding, solid-state phase transition, etc.

However, there is a lack of methods and instruments that can accurately

measure material modulus and internal friction at the same time.

Commercial DMA can only be used to measure polymer soft materials with

small modulus and large damping, but the measurement results of hard

materials are inaccurate, especially since the measurement deviation of

internal friction is very large. At present, the measurement method of

hard material modulus is mainly the free beam vibration method of the

American ASTM standard, but the accuracy of this method is very poor.

The internal friction of hard materials is mainly measured by the

Ke-type pendulum method proposed by the famous metal physicist Ke

Ting-sui, but this method can only measure the torsional internal

friction of filament samples. Its measurement of shear modulus is not

accurate, and the measurement process is cumbersome, so it is difficult

to realize automatic measurement.

Prof. Li Faxin’s group proposed a modulus and internal friction

measurement method based on electro-mechanical impedance method, which

can accurately and quickly measure the Young's modulus, shear modulus,

and corresponding internal friction of materials (Rev SciInstrum 2020,

Editor’s Pick, https://doi.org/10.1063/1.5135360;J App Phys 2020, Invited Perspective & Featured Article, https://doi.org/10.1063/5.0034801).

On this basis, they realized automatic measurement, increased the

measurement temperature to 1300 ⁰ C, and developed this high-temperature

DMA suitable for hard materials. In fact, this method is not sensitive

to temperature, as long as the temperature of the heating furnace can be

reached, there is no problem if the measurement range is above 2000 ⁰

C.

Using this new DMA, the research group obtained the grain boundary

sliding internal friction peak in polycrystalline pure aluminum under

high-frequency vibration (tens of kHz) for the first time, and the peak

temperature reached nearly 500 ⁰ C, which is much higher than the

low-frequency internal friction peak (285 ⁰ C) discovered by academician

Ke Ting-sui in 1947 (Xie, Li, J Alloy Comp 2021, https://doi.org/10.1016/j.jallcom.2021.159556).

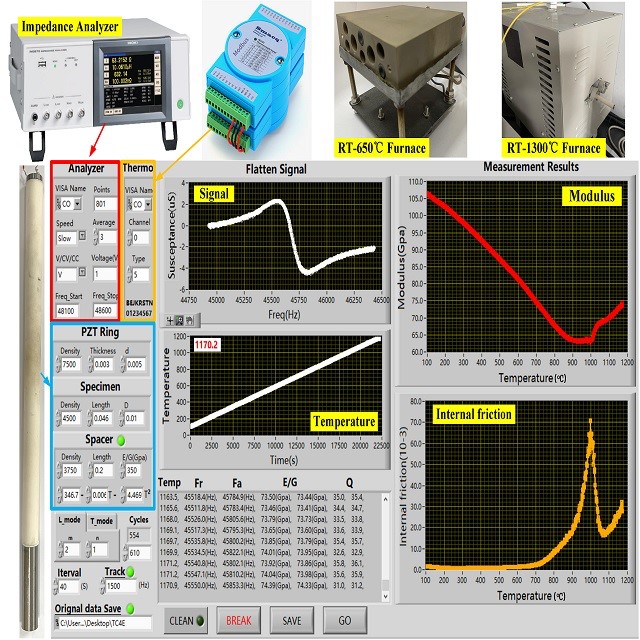

Figure 2 shows the results of measuring the modulus and internal

friction of TC4 titanium alloy from room temperature to 1200 ⁰ C using

the new DMA. It can be seen from the figure that near 990 ⁰ C, both

moduli reach the minimum and both internal friction peak, indicating

that the material has undergone a solid-state phase transition

(transformation from the α+β mixed phase to β phase). It can also be

observed that when the material temperature rises above 700 ⁰ C, the

internal friction begins to rise sharply, which indicates that the

working temperature of TC4 must not exceed 700 ⁰ C. This work was

recently published online in an authoritative journal in the field of

metal materials (https://doi.org/10.1016/j.scriptamat.2021.114435).

Moduli

and internal friction spectrum of TC4 titanium alloy from room

temperature to 1200 ⁰ C. Young's modulus and longitudinal vibration

internal friction (left); shear modulus and torsional internal friction

(right).

Written by: Cherlin Xu

Edited by: Ng Joong Hwee, Fu Jiaqi

Source: PKU News (Chinese)