3D micro strain gauges promote sensing capabilities of electronic skins

Sep 11, 2024

Peking University, September 11, 2024: Imagine that a set of flexible tactile sensors adheres to the surface of your skin, offering customizable detection of biomechanical signals from various body parts. That fiction-like supermaterial is fast weaved into reality.

In a recent study published in the journal Science Advances, researchers from Peking University developed a set of flexible, modular tactile sensors utilizing 3D micro strain gauges as sensing units, achieving high-density mapping of pressure, wireless monitoring of biomechanical signals, and decoupled measurement of temperature, normal force, and shear force.

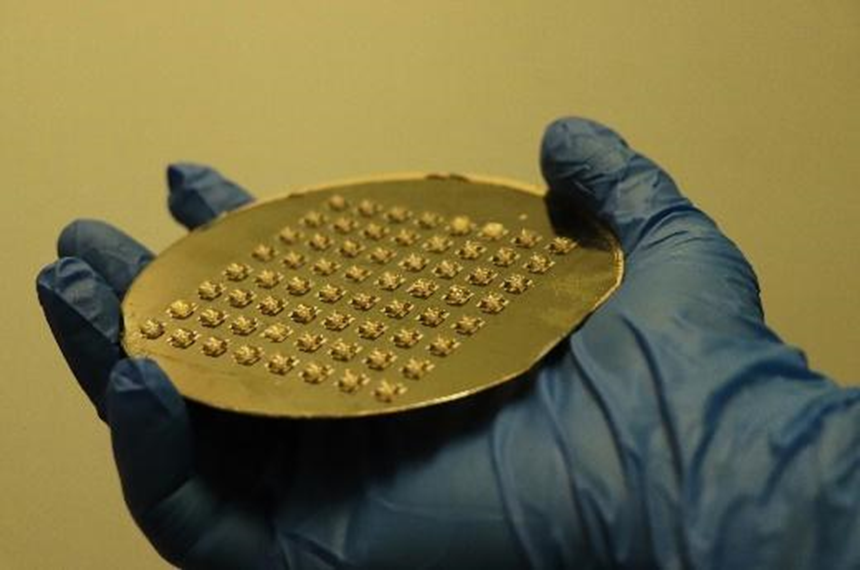

Han Mengdi from Peking University, the corresponding author of this paper, has voiced a positive outlook on this work's potential. "These 3D micro strain gauges offer exciting possibilities for developing flexible tactile sensors and electronic skins," Han said. "By transforming planar strain gauges into 3D forms using a process compatible with lithographic techniques, we can expand the sensing modality and improve the spatial density in tactile sensing.”

The 3D micro strain gauges driven by thin film stress exhibit good consistency and stability, demonstrating excellent parallelization and mass processing capabilities. The process is fully compatible with microfabrication (the process of fabricating miniature structures of micrometer scales and smaller), and the fast and stable transfer method allows for seamless integration with microelectronics and microelectronics.

"Based on the processing technology of 3D micro strain gauges, we can quickly customize the performance of sensors," said Chen Xu, a Ph.D. student in Han's lab and a co-first author of the paper. "By adjusting the shape of the 3D microstructure, the thickness of each layer of thin film, and the thickness of the encapsulating polymer, the sensitivity and other properties of the tactile sensor can be easily changed." This provides a solid foundation for quickly customizing flexible tactile sensors and electronic skins that meet various needs.

"Each flexible sensor contains four 3D micro strain gauges oriented orthogonally, allowing precise decoupling of normal force and shear force to determine the direction and magnitude of external forces. The sensor also incorporates a temperature sensing module," said Wang Yiran, a Ph.D. Student in Han's lab and a co-first author of the paper. "We also designed an anti-crosstalk circuit to support the spatiotemporal mapping of normal and shear forces at the skin interface using an array of our 3D micro strain gauges," Wang added.

These 3D micro strain gauges show compatibility with both microelectronics and macroelectronics and provide opportunities for potential applications from robotics to biomedicine and consumer electronics. This technological approach enhances the sensing performance and integration solutions of flexible tactile sensors, heralding enormous opportunities in microelectronics and microelectronics.

The paper, titled "3D micro strain gauges as flexible, modular tactile sensors for versatile integration with micro- and macroelectronics," was supported by the National Natural Science Foundation of China (No. 62104009); the National Key R&D Program of China (No. 2023YFB3208100); the Emerging Engineering Interdisciplinary Project, Peking University, the Fundamental Research Funds for the Central Universities; and Peking Nanofab Laboratory.

Link to the paper: https://doi.org/10.1126/sciadv.adp6094

Source: College of Future Technology

Edited by: Dennis Meng