Peking University, June 27, 2025: Addressing the challenge of waste plastics treatments, the scientific community has been pursuing innovative solutions. Recently, Peking University researchers led by Ma Ding from College of Chemistry and Molecular Engineering, in collaboration with Xu Shutao from Dalian Institute of Chemical Physics, Chinese Academy of Sciences, uncovered how complex plastic mixtures can be utilized based on the differences in the physical and chemical properties of the components with the aids of NMR technique and catalytic approaches. This work provides a new treatment strategy for recovering real-life plastics and maximizing their potential as raw materials. Their findings, entitled “In-line NMR Guided Orthogonal Transformation of Real-life Plastics,” were published in

Nature on June 25, 2025.

Why it matters:

The global accumulation of plastic waste poses a serious threat to wildlife and ecosystems. Chemical recycling and upcycling technologies offers a promising solution by transforming waste plastics into valuable products, while currently most of them primarily handle single components or polymers with a same structural characteristic. However, efficient recycling of plastic mixtures remains challenging due to their complex composition and structural heterogeneity. However, there is still a lack of effective solutions for real-world plastic waste characterized by complex structures, diverse types, and vastly differing properties.

Methodology:

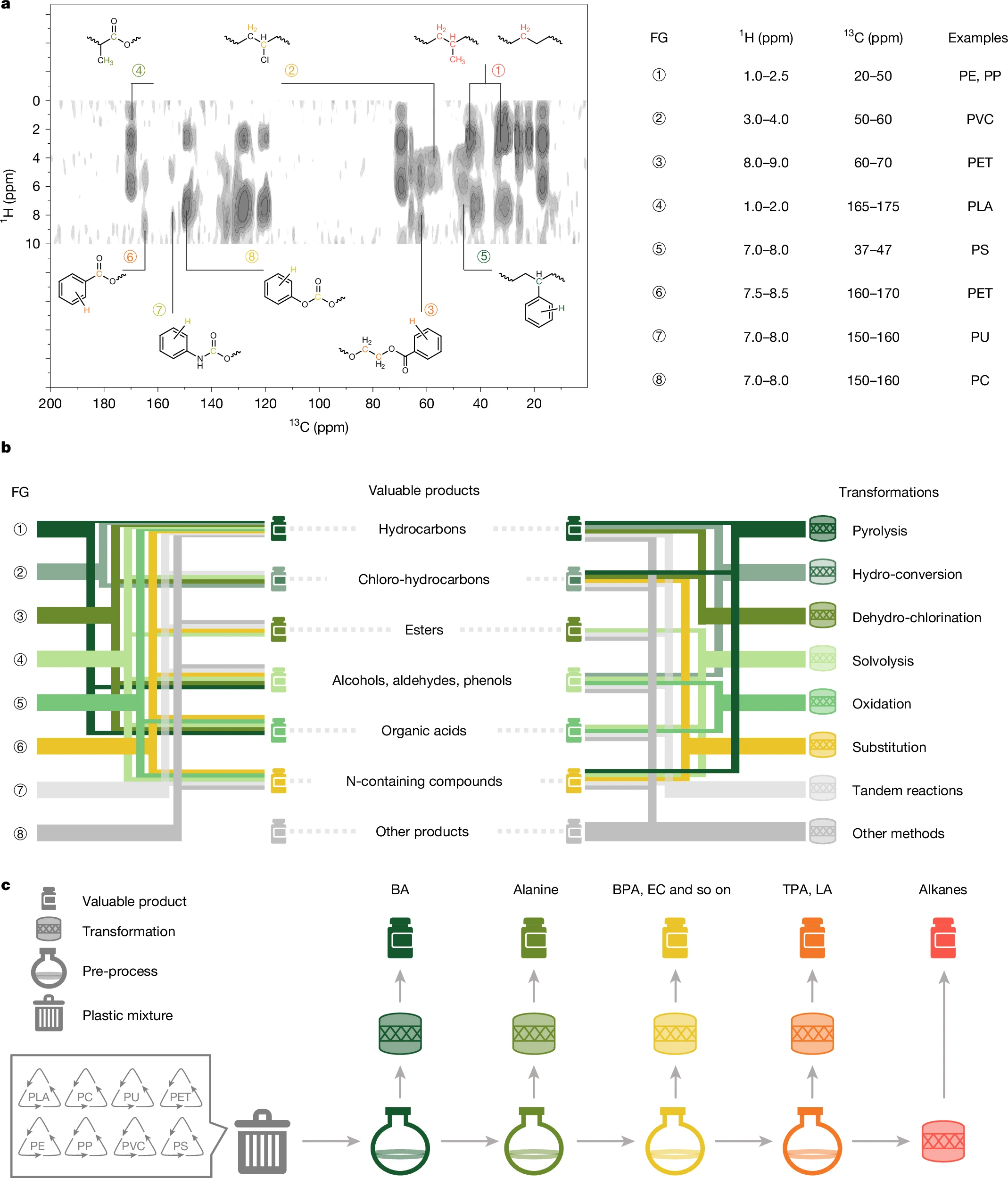

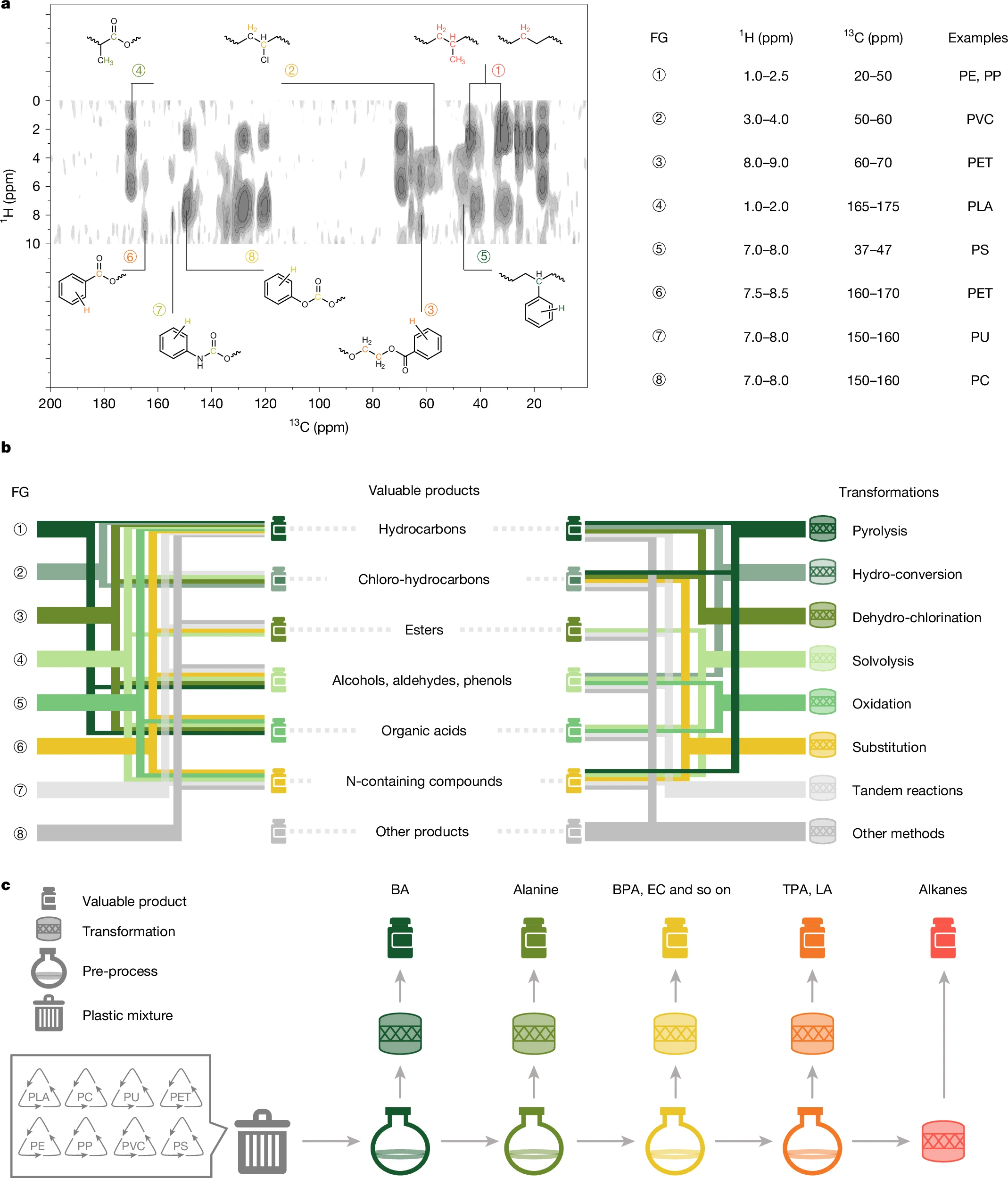

The mixed plastic samples were first analyzed by solid-state NMR technique (two-dimensional 1H–13C frequency-switched Lee–Goldburg heteronuclear correlation) to make a reliable identification of the functional groups in the intermingled matrix. Then, to design suitable transformation routes for desired products, catalytic reactions including photo-oxidation, amination, dehydrogenation coupling and hydrocracking were arrayed with solvent-based pre-processes such as selective dissolution and solvolysis reactions interspersed. To cope with the unknown real-world waste, strategically integration of solid-state NMR with complementary techniques such as solution-state NMR, elemental analysis, vibrational spectroscopy, photoelectron spectroscopy and so on was employed.

Key findings:

1. This study innovatively proposed a product-oriented orthogonal transformation strategy, which is based on accurate identification of the characteristic functional groups, utilized the differences in the physical and chemical properties of different plastic components, and is designed in a targeted manner to convert different types of plastics into valuable chemicals in sequence under mild and low-energy conditions.

2. This strategy successfully achieved the directional preparation of mixed plastics into a variety of valuable products. Started with 20g of real-life plastic mixtures composed of polystyrene, polylactic acid, polyurethane, polycarbonate, polyvinyl chloride, polyethylene terephthalate, polyethylene and polypropylene commodities, a group of useful chemicals were obtained, including 1.3 g of benzoic acid, 0.5 g of plasticizer, 0.7 g of alanine, 0.7 g of lactic acid, 1.4 g of aromatic amine salts, 2.1 g of bisphenol A, 2.0 g of terephthalic acid and 3.5 g of C3-C6 alkanes.

3. The NMR guided orthogonal strategy can effectively analyze and transform unknown waste samples—such as mixtures of various plastic commodities in daily life, samples from refineries, auto repair shops, and the textile industry—demonstrating its feasibility and robustness in real-world plastic waste management.

4. The study proposed a highly adjustable waste resource conversion strategy, under which each specific processing step can be improved and optimized according to the characteristics of the raw materials, the target product requirements and technological progress, in order to maximize the economic and environmental benefits.

This groundbreaking study opens up a new avenue for treating real-life plastic waste, offering hope for more efficient and sustainable utilization of plastic resources for the production of a variety of valuable products.

Figure 1. Proposed strategy for the recovery of mixed plastics

*This article is featured in PKU News "Why It Matters" series. More from this series.

Read more:

https://www.nature.com/articles/s41586-025-09088-7

Written by: Ma Ding, Xu Shutao

Edited by: Zhang Jiang

Source: College of Chemistry and Molecular Engineering, Peking University