Peking University, September 9, 2025: A research team led by Professor Lei Ting from the School of Materials Science and Engineering has made the first “thermoelectric rubber.” This elastic thermoelectric material combines high energy conversion efficiency, exceptional stretchability, and skin-conformal flexibility, making it ideal for powering wearable electronics (Figure 1). Their study, titled “N-Type Thermoelectric Elastomers,” has been published in

Nature on August 13.

Background

Thermoelectric devices convert body heat into electricity, offering a sustainable power source for wearable and bioelectronic systems. Inorganic materials, such as Bi₂Te₃ and PbTe, deliver high efficiency but are brittle and rigid, while organic thermoelectrics are flexible yet lose performance under strain and lack skin conformability. The challenge has been to combine high thermoelectric efficiency with rubber-like elasticity.

Why it matters

The thermoelectric elastomer, also known as “thermoelectric rubber,” addresses these limitations by achieving high thermoelectric performance and mechanical resilience. This breakthrough enables wearable devices to generate continuous power from body heat while remaining comfortable and adaptive during movement, opening new opportunities for self-powered electronics and solid-state cooling systems.

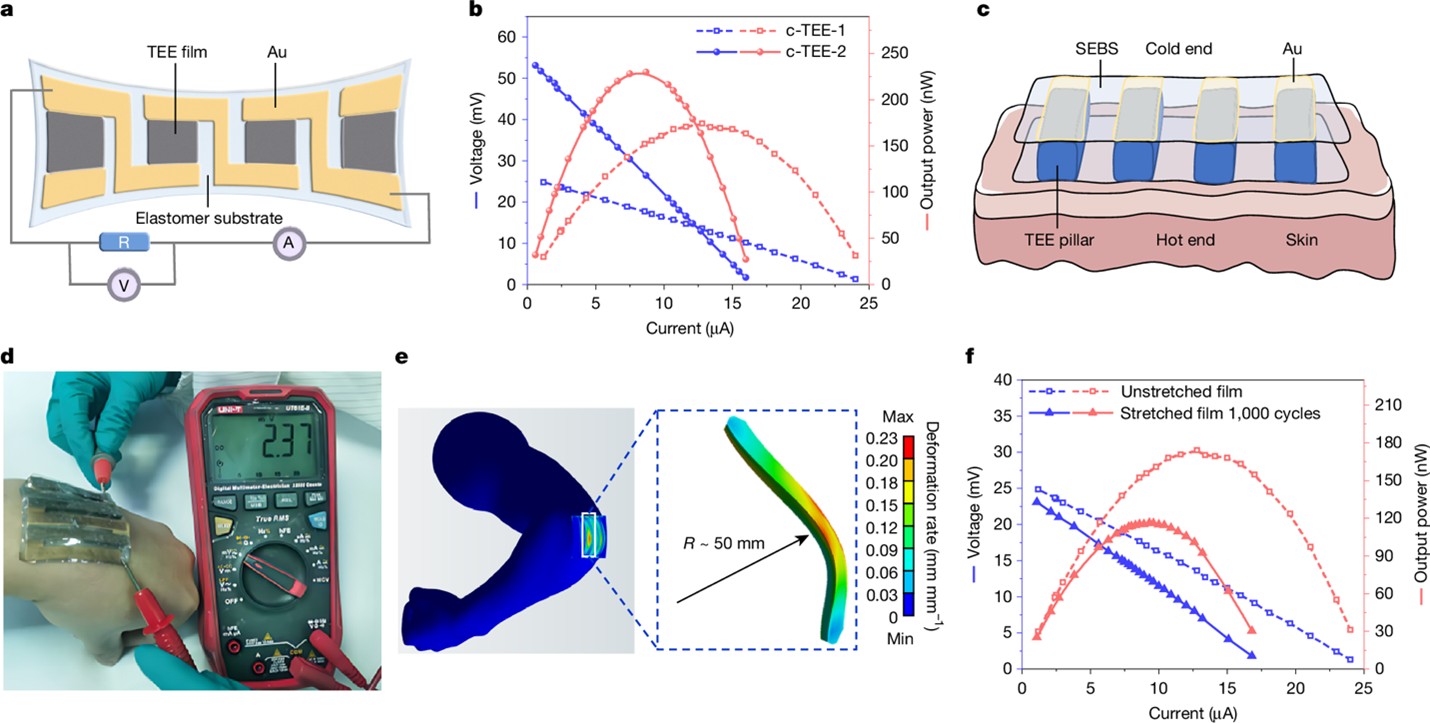

Fig. 1 Design strategy of N-type thermoelectric elastomers.

Key Findings

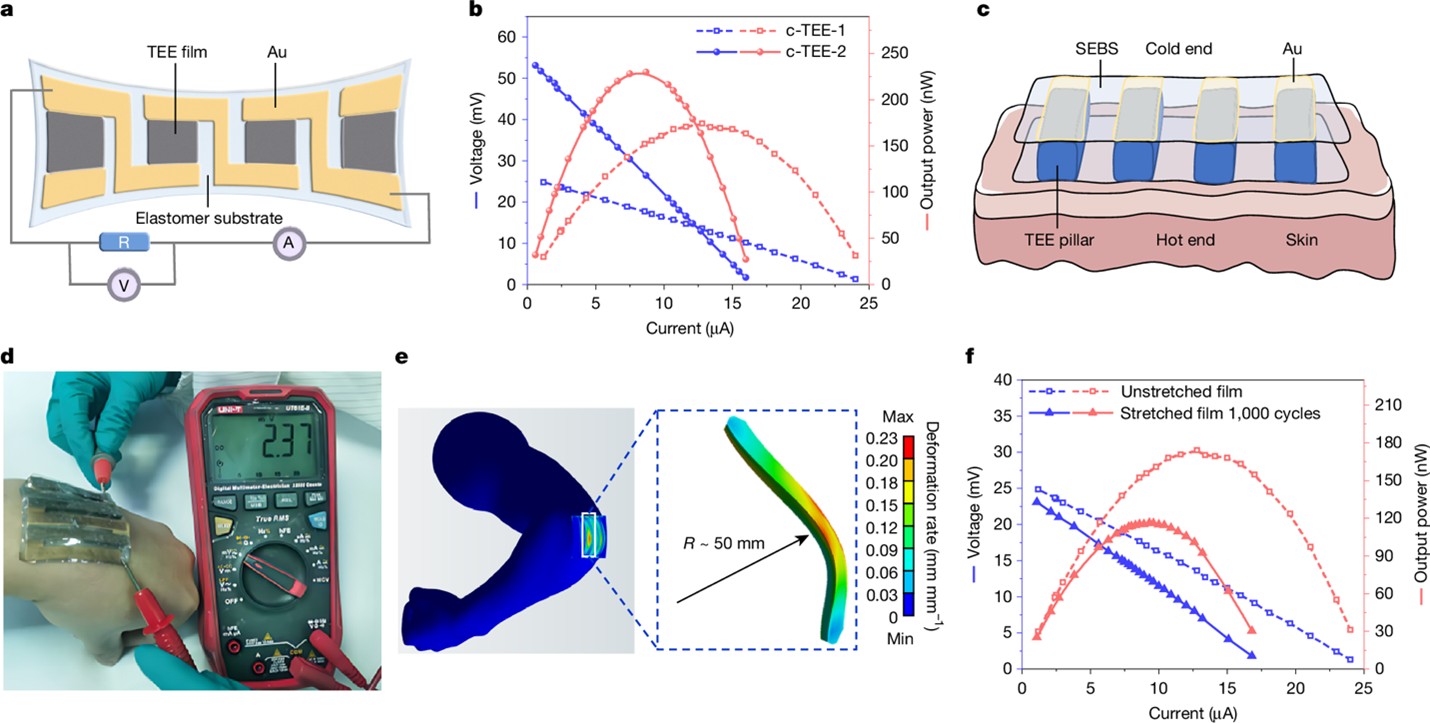

Professor Lei Ting’s team developed the thermoelectric rubber using three key strategies: nanoscale phase separation to create a conductive nanofiber network that boosts carrier mobility and conductivity; thermo-activated crosslinking to achieve over 850% stretchability with 90% elastic recovery at 150% strain; and directional doping to enhance both conductivity and the Seebeck coefficient while preserving elasticity. These innovations improved mechanical resilience and lowered thermal conductivity through interfacial phonon scattering, yielding a thermoelectric figure of merit (ZT) of 0.49 at room temperature, comparable to or surpassing flexible and plastic inorganic thermoelectric materials (Figure 2).

Fig. 2 Fabrication and measurement of the intrinsically elastic thermoelectric generators (TEGs).

Future Implications

This work represents a major step toward self-powered wearable electronics and flexible cooling devices. By combining efficiency with comfort, the study paves the way for next-generation, skin-friendly energy harvesting technologies.

*This article is featured in PKU News "Why It Matters" series. More from this series.

Read more: https://www.nature.com/articles/s41586-025-09387-z

Written by: Akaash Babar

Edited by: Zhang Jiang

Source: PKU News (

Chinese)